Features

Descriptions:

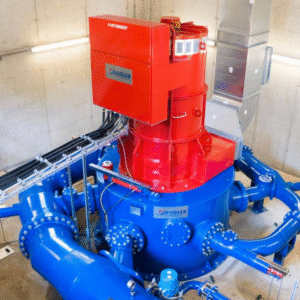

Francis ASUMB Turbine: A Detailed Review, Advantages, and Applications for Hydroelectric Power Plants

The Francis Turbine ASUMB is a highly efficient Austrian hydroelectric power unit designed for medium- and high-pressure hydroelectric power plants. Its profiled blade design and optimized flow ensure maximum efficiency, reliability, and durability, making it a versatile solution for industrial and small hydroelectric power plants.

The equipment is manufactured in Austria with quality control at all stages, guaranteeing cavitation resistance and a service life of up to 50 years.

Contents of the article

Features of the Francis ASUMB turbine

The ASUMB Francis turbine is designed for heads of 10–300 meters and a wide range of flow rates. Optimized blades and hydraulic circuits enable efficiency of 90–94%, ensuring maximum energy production in medium and large hydroelectric power plants.

Benefits and effectiveness

High efficiency at medium and high pressures

Stable operation with seasonal and short-term fluctuations in water consumption

Versatility for small, medium and large hydropower plants

Suitable for modernization of old Soviet hydroelectric power stations

Adaptability to water consumption

The ASUMB Francis turbine maintains high efficiency even with changing water flow rates due to:

adjustment of the guide vane

optimized blade pitch angle

This adaptability prevents overloads and cavitation, ensuring safe and economical operation.

Reliability and service life of equipment

The design includes:

cast and high-strength impeller blades

anti-corrosion coatings

high-precision bearing units

hydraulically balanced rotor

With proper operation, the service life of a turbine reaches 40–50 years.

Maintenance and operating costs

Turbine maintenance is simple and cost-effective. Basic procedures:

checking the condition of the blades

inspection of bearings and seals

control system diagnostics

Routine maintenance is carried out once every 12–18 months, and major repairs are carried out once every 10–15 years, which reduces operating costs.

The working principle of the Francis turbine ASUMB

Water is supplied through a guide vane, creating an optimal flow.

The flow acts on an impeller with profiled blades.

The energy of the water is transferred to the shaft, which rotates the generator.

The generator produces electricity.

This scheme ensures stable and efficient operation under any hydrological conditions.

Where are ASUMB Francis turbines used?

Medium and large hydroelectric power plants

River and diversion hydroelectric power plants

Modernization of old Soviet hydroelectric power plants

Industrial facilities, quarries and mines

Autonomous stations in hard-to-reach regions

Particularly relevant for the regions: Kazakhstan, Kyrgyzstan, Georgia, Armenia, Russia (Siberia, Altai), Caucasus.

Why choose ASUMB and our company

We provide a full cycle of project implementation:

ASUMB turbine production (Austria)

Design of hydroelectric power plants of any capacity: hydraulic calculations, 3D modeling, feasibility studies, working designs

Supply, installation, commissioning and start-up

Financing: bank loans, preferential programs, private investment, leasing

Coordination of documentation: ecology, feasibility study, design documentation, state expert assessments

Warranty and service: scheduled inspections, spare parts supply, equipment upgrades

Conclusion

The Francis Turbine ASUMB is a reliable, highly efficient, and durable solution for medium- and high-pressure hydroelectric power plants. Austrian quality and optimized design ensure stable power generation, and our company guarantees a full turnkey implementation cycle—from design and approvals to installation, commissioning, and project financing.

Examples of completed projects

The Glarey hydroelectric project is located in Switzerland.

A site for the construction of a mini-hydroelectric power station on the Lodnari River (Georgia)

The Akavreta-Lodnari hydroelectric power station is located on a watercourse with a stable seasonal flow

The Gudauri hydroelectric power station is a high-pressure mountain station with a significant difference in elevation.

Akavreta hydroelectric power station is an object for implementation/joint investment

Combined model "Shrosha - Dzirula"

Mini-hydropower plants in Kyrgyzstan. Construction sites and modernization of existing hydropower plants

Sale of land and construction of mini-hydroelectric power plants in Kazakhstan

Project cascade mini-hydroelectric power station on the river Arym

An inactive mini-hydroelectric power plant in the Almaty region is for sale.

Hydroelectric power station for sale in Zukhzidi, Georgia.

Pobreg (Small Unit), Albania — 2012

Obuse Hydroelectric Power Station, Japan – 2018

La Yeguadita Hydroelectric Power Station, Panama – 2018

ASUMB Hydropower Station Rugezi, Rwanda — 2016

Rwaza I, Rwanda—supply kit and project parameters

Supply of Kaplan turbines ASUMB United Kingdom

Cartiera del Maglio Hydroelectric Power Plant – EPF, Italy, 2011

Nuevo Imperial Hydroelectric Power Station, Peru, 2011

Teacher, Guyana, 2025

Sleitustaða Power Plant, Iceland, 2019

Royal Park, Italy, 2017

Pencaligue 2, Honduras, 2016

Sale of land in Georgia, Kyrgyzstan, Kazakhstan, and Armenia for the construction of a hydroelectric power station

Haut Fournel, France, 2024