Pelton turbine peltona ASUMB

The Pelton turbine is an impulse turbine specifically designed for high heads and low flow rates. It is used on mountain rivers, streams, water intakes with large elevation differences, and facilities where high flow rates are unachievable but significant head is available.

Typical application parameters:

pressures from 100 to 1500 meters,

flow rates from 50 to 1500 l/s,

Ideal for mini-hydroelectric power plants and small hydroelectric power plants in mountainous regions, gorges, canyons, alpine and high-mountain locations.

The ASUMB Pelton turbine allows for maximum energy production even where conventional turbines (Francis or Kaplan) cannot operate.

Features

Descriptions:

ASUMB Pelton Turbine: A Complete Overview, Advantages, and Applications for Hydroelectric Power Plants

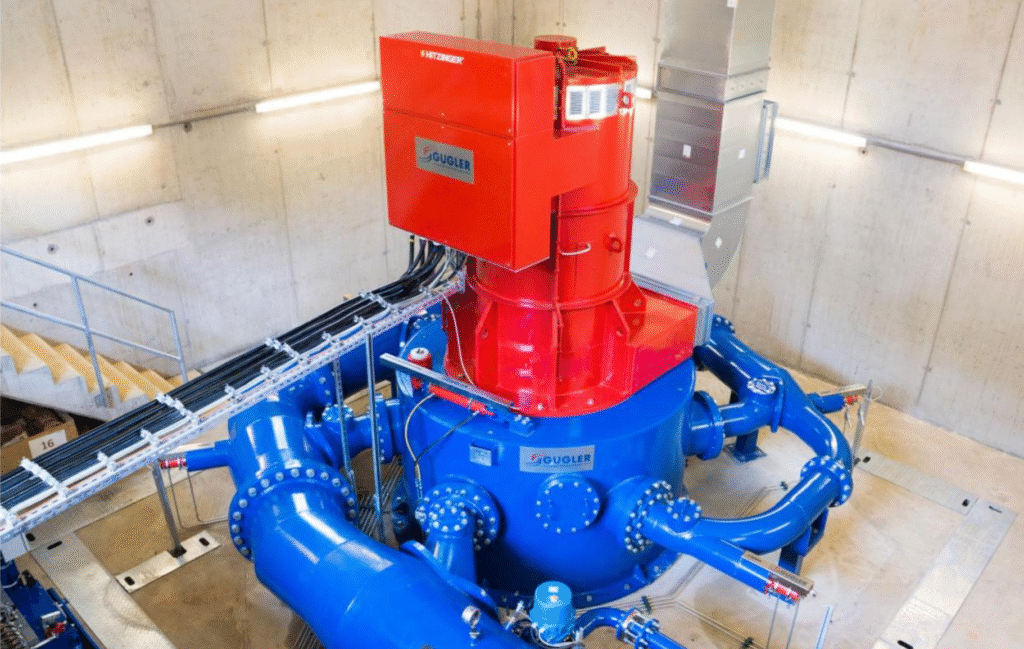

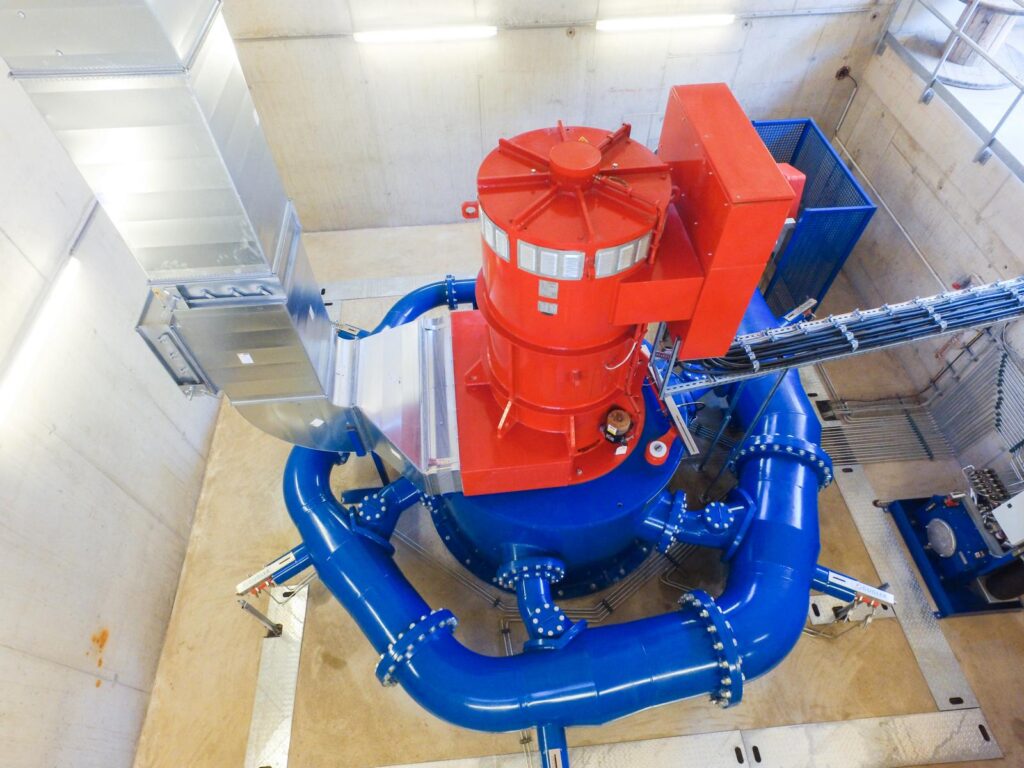

The Pelton Turbine ASUMB is an Austrian hydroelectric power equipment developed for high-pressure hydroelectric power plants. The turbine's design efficiently converts the energy of narrow water jets into mechanical rotation, ensuring maximum efficiency and a long service life even in challenging hydrological conditions.

The equipment is manufactured in Austria according to strict European standards, which guarantees reliability, durability, and resistance to cavitation.

Contents of the article

Features of the ASUMB Pelton turbine

The ASUMB Pelton turbine is designed for high-pressure, low-flow applications. Its key feature is its pulse design, where a narrow water jet strikes the impeller bucket, transferring nearly all of its energy.

The turbine efficiency reaches 90–93%, which is one of the best indicators in the class of high-pressure hydroturbines.

Benefits and effectiveness

High efficiency at high pressures

Efficient operation on seasonal and unstable water flows

Suitable for the reconstruction of old hydroelectric power plants and the construction of new high-pressure stations

Versatility for industrial, municipal and small hydropower plants

Reliability and durability

The ASUMB Pelton turbine is distinguished by Austrian quality:

high-strength cast buckets

anti-corrosion coatings

balanced rotor

high-quality bearing units

The service life of the equipment is 30–50 years with proper operation.

Ease of maintenance and operating costs

The ASUMB Pelton turbine requires minimal maintenance and does not require complex hydraulics:

checking injectors

inspection of buckets

inspection of seals and bearings

Routine maintenance is carried out once every 12–18 months, and major repairs are carried out once every 10–15 years, which reduces operating costs.

The working principle of the Pelton turbine ASUMB

Water is supplied through a pressure water pipe and nozzles, forming a narrow stream.

The jet hits the impeller bucket, changing direction by 180° and losing almost all of its energy.

The energy of the water is transferred to the shaft, driving the generator.

The generator produces electricity.

The pulse principle ensures stable, safe and economical operation at high pressures.

Where are ASUMB Pelton turbines used?

High-pressure hydroelectric power plants

Mini hydroelectric power plants on mountain rivers and streams

Autonomous stations in hard-to-reach regions

Municipal and industrial micro-hydroelectric power plants

Reconstruction of old Soviet hydroelectric power plants

Particularly suitable for Kyrgyzstan, Kazakhstan, Georgia, Armenia, Altai, the Caucasus and any mountainous areas.

Why choose ASUMB and our company

We provide a full cycle of implementation of ASUMB Pelton turbines:

Manufacturing and supply of original equipment from Austria

Design of hydroelectric power plants of any capacity: hydraulic calculations, 3D modeling, feasibility studies

Installation, commissioning and start-up

Financing: bank loans, preferential programs, private investment, leasing

Coordination of documentation: ecology, feasibility study, design documentation, state expert assessments

Warranty and service: scheduled inspections, spare parts supply, equipment upgrades

Conclusion

The Pelton Turbine ASUMB is a reliable, highly efficient, and durable solution for high-pressure hydroelectric power plants. Austrian quality, simple design, and high efficiency ensure stable power generation, and our company provides a full range of services—from design and approvals to installation, commissioning, and project financing.

Examples of completed projects

Mini-hydropower plants in Kyrgyzstan. Construction sites and modernization of existing hydropower plants

Sale of land and construction of mini-hydroelectric power plants in Kazakhstan

Project cascade mini-hydroelectric power station on the river Arym

An inactive mini-hydroelectric power plant in the Almaty region is for sale.

Hydroelectric power station for sale in Zukhzidi, Georgia.

Haut Bens Hydroelectric Power Station, France – 2020

Bodorna Hydroelectric Power Station, Georgia – 2018

ASUMB Cutzán, Guatemala – 2017

ASUMB Hintergössgraben, Austria — 2017

ASUMB HPP Vordergössgraben Hydroelectric Power Station, Austria

Rwaza I, Rwanda—supply kit and project parameters

Supply of Kaplan turbines ASUMB United Kingdom

Cartiera del Maglio Hydroelectric Power Plant – EPF, Italy, 2011

Nuevo Imperial Hydroelectric Power Station, Peru, 2011

El Sindigo Project, Panama, 2011

Pencaligue 2, Honduras, 2016