Features

Descriptions:

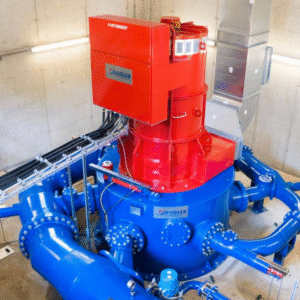

ASUMB Kaplan Turbine: A Complete Overview, Advantages, and Applications for Hydroelectric Power Plants

The Kaplan Turbine ASUMB is a high-tech Austrian hydropower device designed for efficient operation at low and medium heads. Its adjustable impeller and guide vane design ensures maximum efficiency even with fluctuating water flow rates.

The equipment is manufactured in Austria to strict quality standards, guaranteeing reliability, durability, and cavitation resistance.

Contents of the article

Features of the Kaplan ASUMB turbine

The ASUMB Kaplan turbine is designed for operation at heads of 2–30 meters and a wide range of flow rates. Adjustable runner and guide vane blades maintain high efficiency of 88–93%, making it an optimal choice for gentle rivers, diversion schemes, and microhydropower plants.

Benefits and effectiveness

High efficiency at low and medium pressures

Efficient operation with seasonal fluctuations in water consumption

Versatility for small and medium-sized hydroelectric power plants

Suitable for modernization of old Soviet hydroelectric power plants

Automatic regulation and adaptability

The ASUMB system synchronously controls:

impeller blade angle

position of the guide vane

Benefits of automation:

stable generation of electricity all year round

minimization of overloads and losses

adaptation to seasonal changes in flow rate without manual intervention

Reliability and durability

The turbine design includes:

reinforced impeller blades

anti-corrosion coatings

precision bearings

cavitation protection

The service life of the equipment reaches 40–60 years with proper operation.

Ease of maintenance and operating costs

Maintenance of the ASUMB Kaplan turbine does not require complex hydraulics. Basic operations:

impeller blade inspection

checking the guide vane

diagnostics of the automatic hydraulic system

bearing inspection

Routine maintenance is carried out every 12–18 months, and major repairs are carried out every 12–20 years, which reduces operating costs.

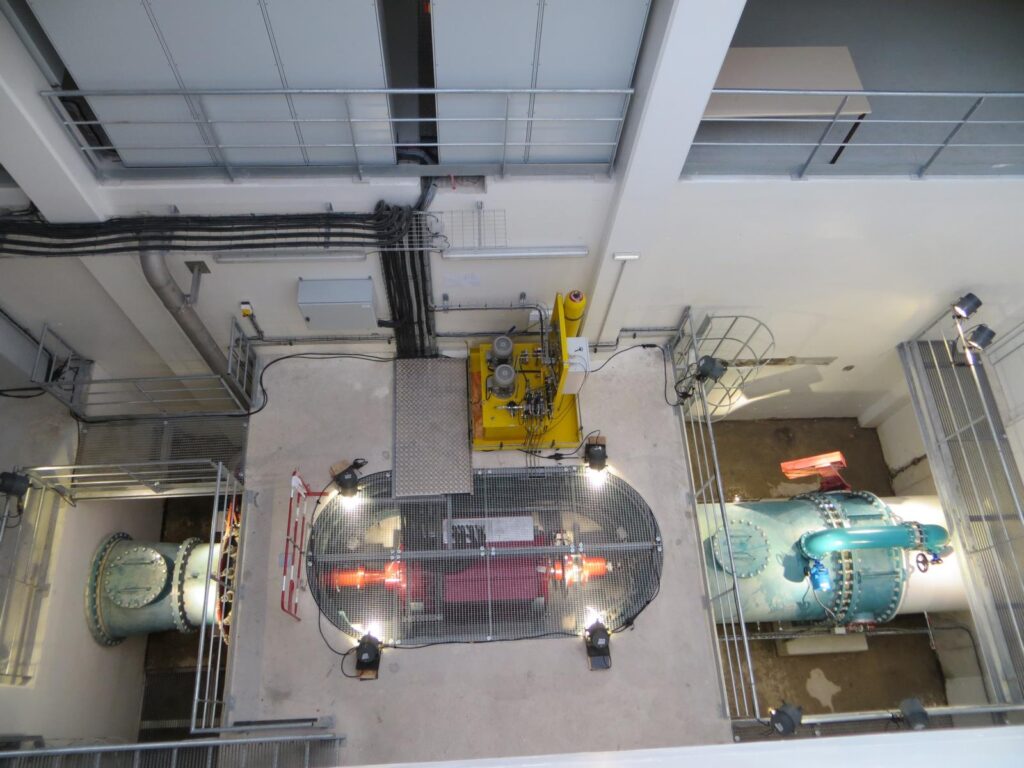

The principle of operation of the Kaplan turbine ASUMB

Water enters through an adjustable guide vane.

The stator blades form an optimal flow direction.

The flow acts on the impeller, where the blades automatically change their angle of inclination.

The energy of the water is transferred to the shaft, driving the generator.

This adaptive scheme ensures high efficiency even on rivers with unstable water flow.

Where are ASUMB Kaplan turbines used?

Small and medium-sized hydroelectric power plants

Diversion stations

Modernization of old Soviet hydroelectric power plants

Urban and rural micro hydroelectric power plants

Autonomous energy facilities for enterprises

Particularly relevant for the regions: Kazakhstan, Kyrgyzstan, Uzbekistan, Georgia, Armenia, Russia (Siberia, Altai), Caucasus.

Why choose ASUMB and our company

We provide a full cycle of project implementation:

ASUMB turbine production (Austria)

Design of hydroelectric power plants of any capacity: hydraulic calculations, 3D modeling, feasibility studies, working designs

Supply, installation, commissioning and start-up

Financing: bank loans, preferential programs, private investment, leasing

Coordination of documentation: ecology, feasibility study, design documentation, state expert assessments

Warranty and service: scheduled inspections, spare parts supply, equipment upgrades

Conclusion

The Kaplan Turbine ASUMB is a versatile, cost-effective, and durable solution for low-head hydropower plants. Austrian quality, adaptable design, and high efficiency make it the best choice for modern hydropower projects. Our company provides a full turnkey implementation cycle, from design to commissioning and financing.

Examples of completed projects

Mini-hydropower plants in Kyrgyzstan. Construction sites and modernization of existing hydropower plants

Sale of land and construction of mini-hydroelectric power plants in Kazakhstan

Project cascade mini-hydroelectric power station on the river Arym

An inactive mini-hydroelectric power plant in the Almaty region is for sale.

Hydroelectric power station for sale in Zukhzidi, Georgia.

ASUMB Clywedog, UK – 2017

Giorlandina Hydroelectric Power Station, Italy – 2017

Rwaza I, Rwanda—supply kit and project parameters

Supply of Kaplan turbines ASUMB United Kingdom

Cartiera del Maglio Hydroelectric Power Plant – EPF, Italy, 2011

Nuevo Imperial Hydroelectric Power Station, Peru, 2011

El Sindigo Project, Panama, 2011

Teacher, Guyana, 2025

Sleitustaða Power Plant, Iceland, 2019

Royal Park, Italy, 2017

Pencaligue 2, Honduras, 2016