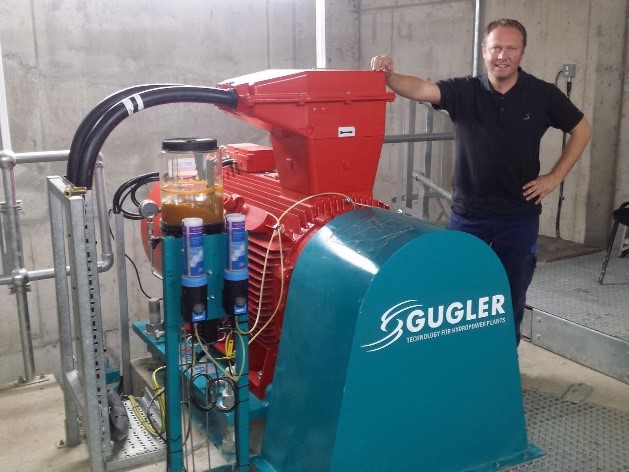

Turbines, Generators, Hydroelectric Power Plant Automation

The latest turbines, generators and automation equipment,

created in our modern factory in Austria

official representatives of GUGLER

Request for proposal

I have read the Privacy Policy

Request for proposal

I have read the Privacy Policy

official representatives of GUGLER

About the company

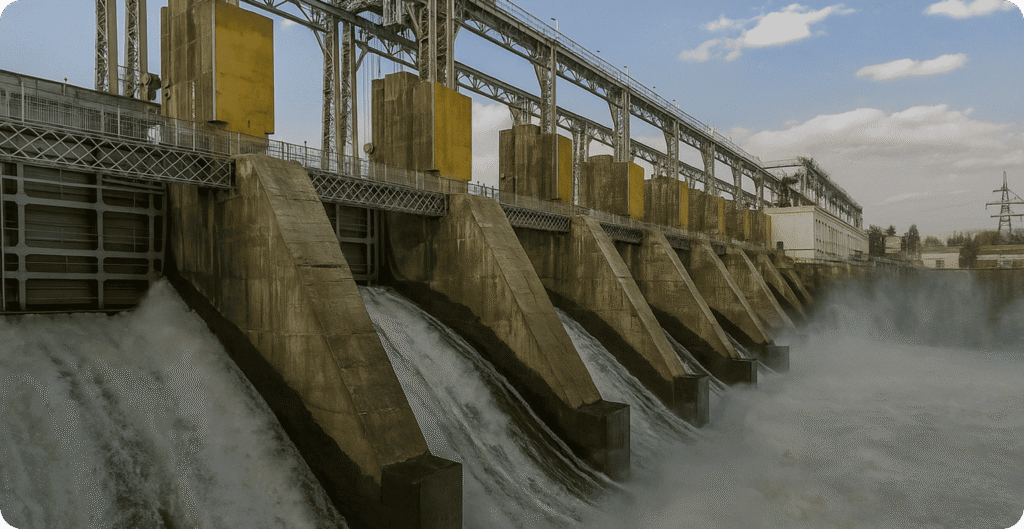

More than 120 completed projects in Russia, Kazakhstan, and Belarus. From small hydropower plants to

largest complexes – we support facilities at all stages of the life cycle

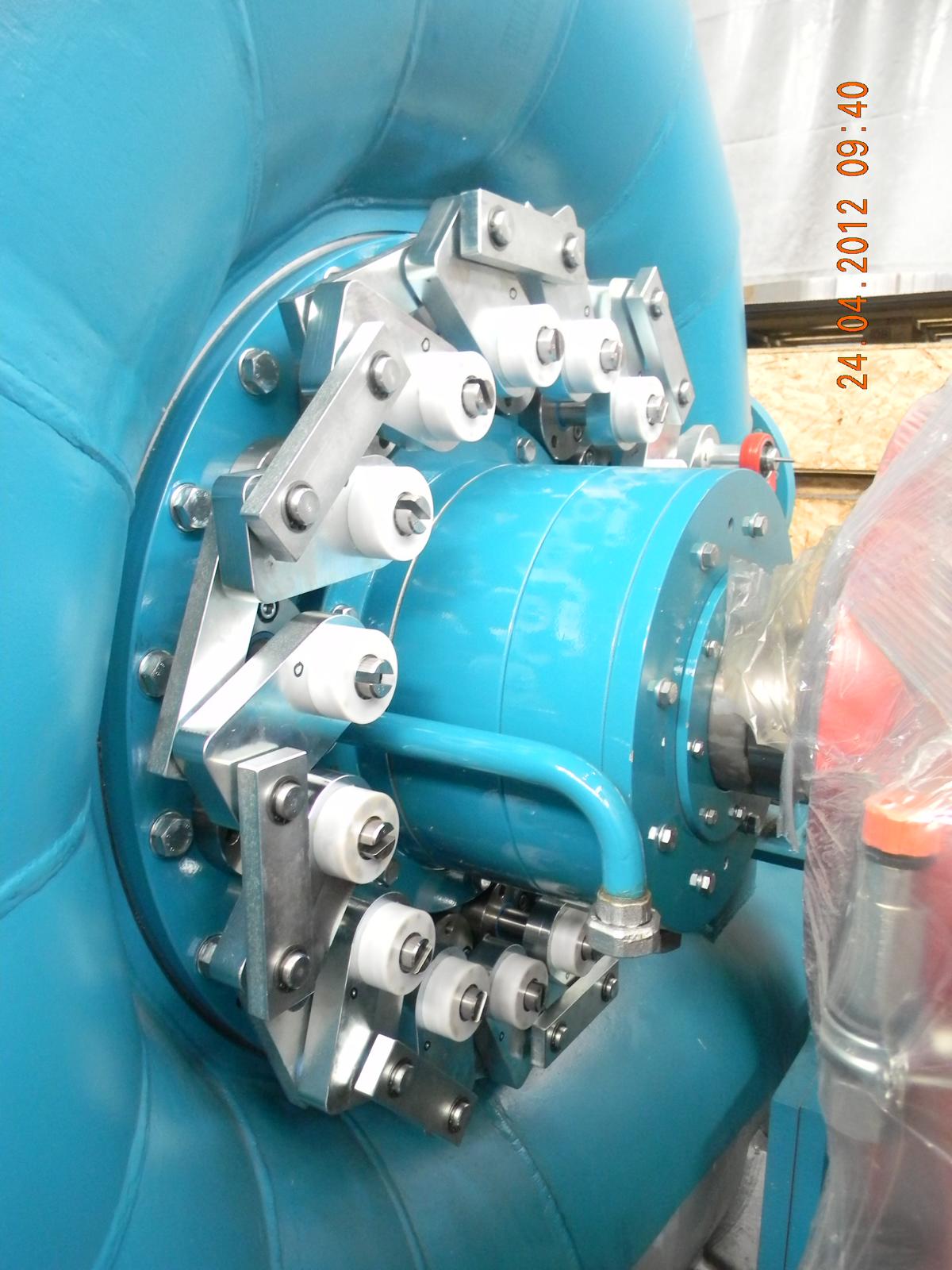

Modernization of obsolete equipment

We provide complete replacement or upgrade of outdated turbines and generators, improving the plant's reliability and efficiency. All solutions are tailored to the specific conditions of the facility.

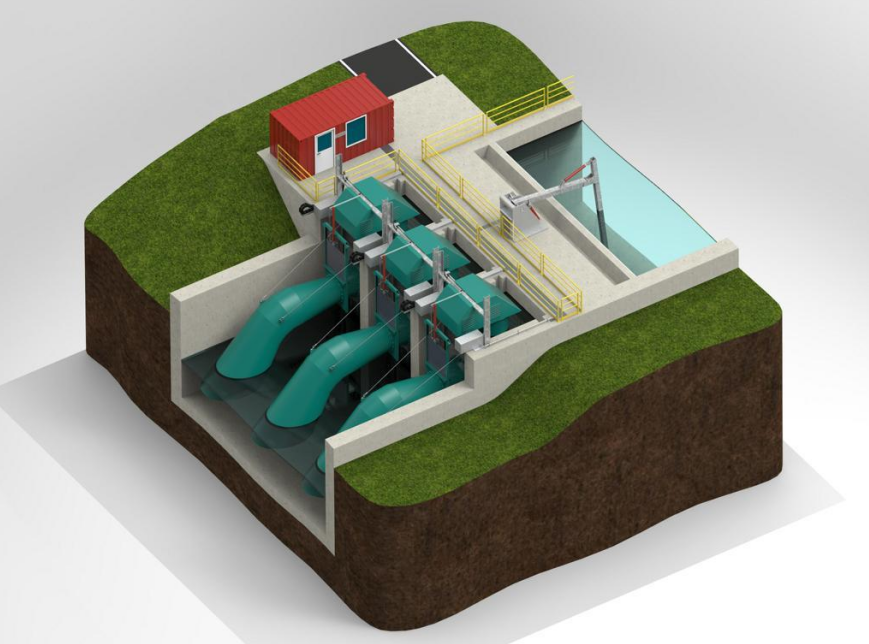

Custom engineering solutions

We design equipment taking into account terrain, pressure, and available space. We use a flexible approach to ensure optimal hydraulic system operation.

Reconstruction of hydroelectric power plants

We are renovating stations built in the last century: replacing mechanical components, strengthening structures, and increasing overall performance and safety.

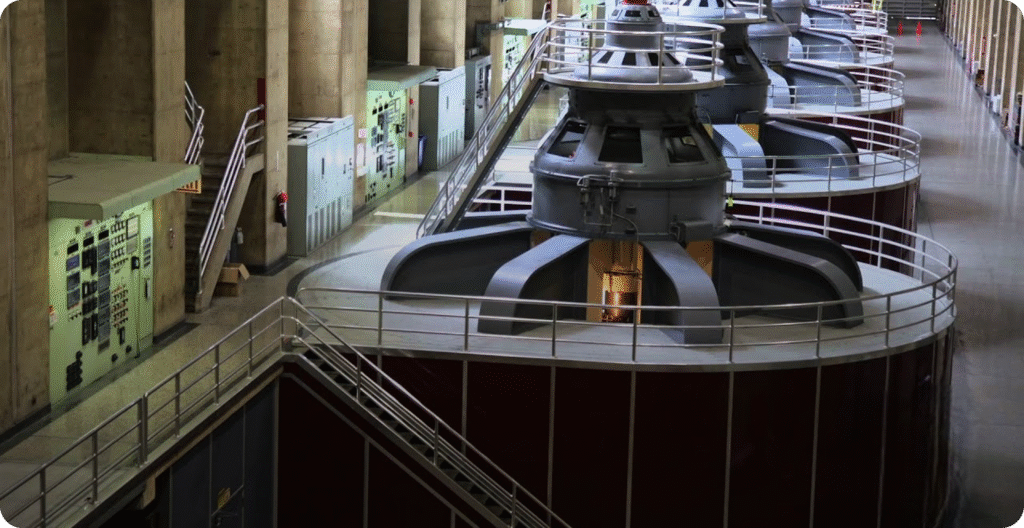

Modern control systems

We install automated systems that monitor station operations in real time and simplify maintenance.

Gugler hydro turbines around the world

Examples of completed projects

Singing, Philippines, 2019

The Glarey hydroelectric project is located in Switzerland.

A site for the construction of a mini-hydroelectric power station on the Lodnari River (Georgia)

The Akavreta-Lodnari hydroelectric power station is located on a watercourse with a stable seasonal flow

The Gudauri hydroelectric power station is a high-pressure mountain station with a significant difference in elevation.

Akavreta hydroelectric power station is an object for implementation/joint investment

Heva Hydroelectric Power Station (project under implementation/investor proposal)

Combined model "Shrosha - Dzirula"

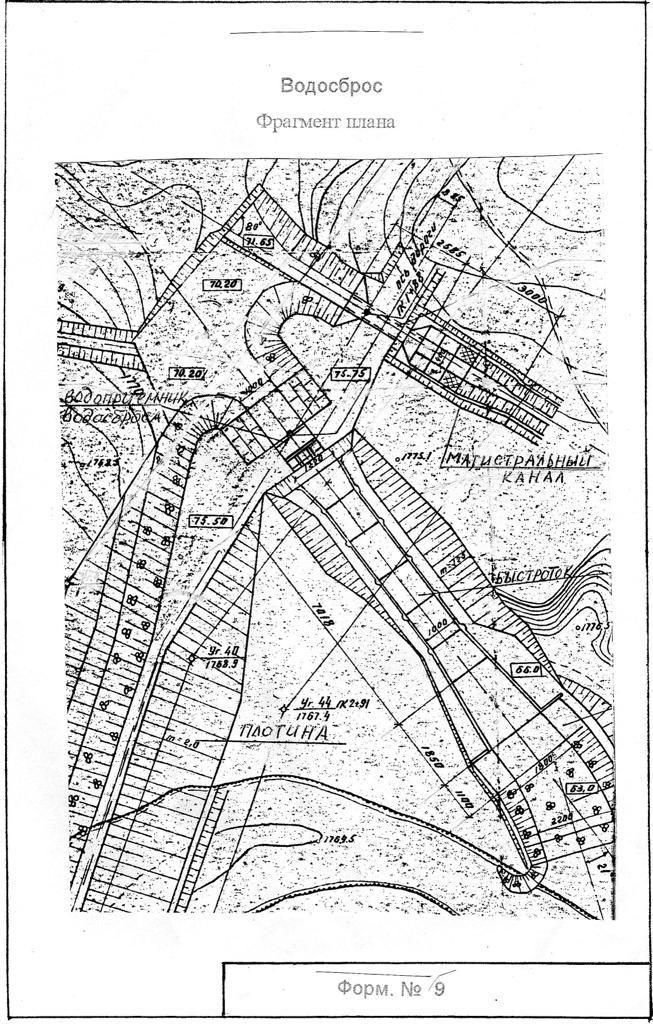

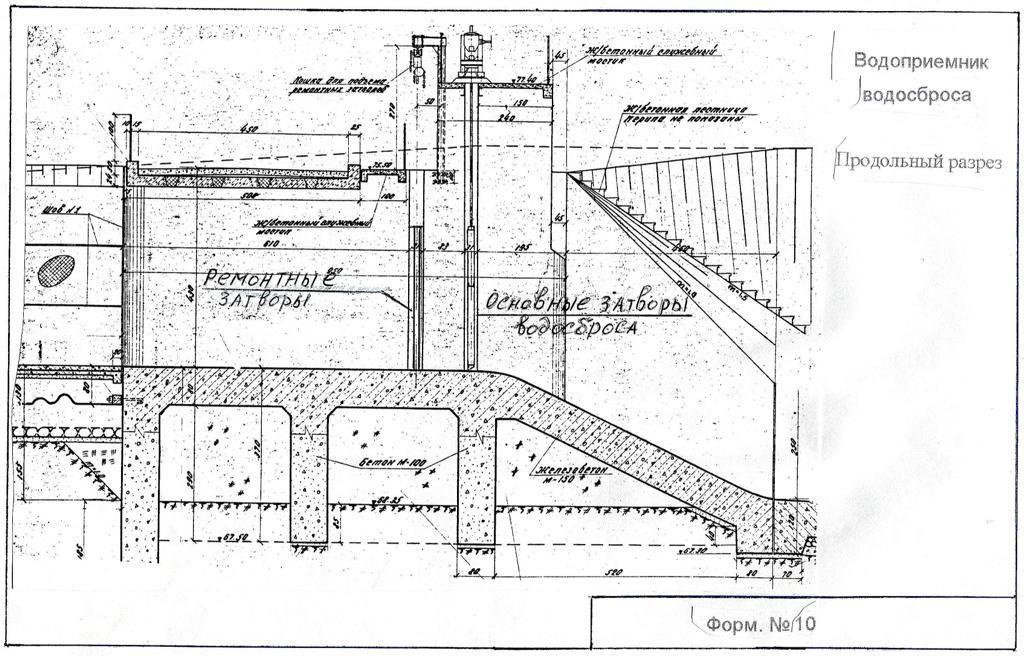

Mini-hydropower plants in Kyrgyzstan. Construction sites and modernization of existing hydropower plants

Sale of land and construction of mini-hydroelectric power plants in Kazakhstan

Project cascade mini-hydroelectric power station on the river Arym

An inactive mini-hydroelectric power plant in the Almaty region is for sale.

Hydroelectric power station for sale in Zukhzidi, Georgia.

Pobreg (Small Unit), Albania — 2012

Haut Bens Hydroelectric Power Station, France – 2020

Obuse Hydroelectric Power Station, Japan – 2018

La Yeguadita Hydroelectric Power Station, Panama – 2018

Bodorna Hydroelectric Power Station, Georgia – 2018

ASUMB Clywedog, UK – 2017

ASUMB Cutzán, Guatemala – 2017

Regio Parco, Italy — 2017

ASUMB Hintergössgraben, Austria — 2017

Giorlandina Hydroelectric Power Station, Italy – 2017

ASUMB HPP Vordergössgraben Hydroelectric Power Station, Austria

ASUMB Hydropower Station Rugezi, Rwanda — 2016

ASUMB Cumpeo Hydroelectric Power Station, Chile – 2016

Rwaza I, Rwanda—supply kit and project parameters

Supply of Kaplan turbines ASUMB United Kingdom

Batu Hampar Hydroelectric Power Station, Indonesia, 2011

Cartiera del Maglio Hydroelectric Power Plant – EPF, Italy, 2011

Nuevo Imperial Hydroelectric Power Station, Peru, 2011

El Sindigo Project, Panama, 2011

Teacher, Guyana, 2025

Sleitustaða Power Plant, Iceland, 2019

Royal Park, Italy, 2017

Pencaligue 2, Honduras, 2016

Strasbourg, France, 2013

Sale of land in Georgia, Kyrgyzstan, Kazakhstan, and Armenia for the construction of a hydroelectric power station

Haut Fournel, France, 2024

Nam Tha 4, Vietnam, 2020

Tanjung Tirta, Indonesia, 2019

Owala, Sri Lanka, 2014

Articles

Contacts

Request for proposal

I have read the Privacy Policy

Address

GUGLER Water Turbines GmbH

Gewerbepark 41, 4101 Feldkirchen-

on the Danube, Austria

Post office